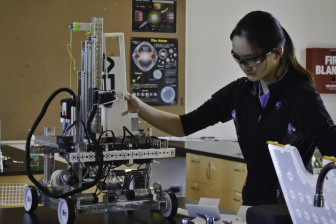

With build season underway, the Aragon Robotics Team (ART) has been working to construct a robot with the least flaws and greatest efficacy in the time span of six weeks. The team takes into account mechanics, electronics, and programming, which all play pivotal roles in ensuring that the robot is complete and functions as desired. They will then take their robot to compete in the FIRST robotics challenge at Silicon Valley Regionals. Because of these interlacing facets of the building process, the team constructs a robot through a series of indistinct steps. Following are the key steps from start to finish of building a robot in ART.

Step 1: Brainstorming

Members of ART, primarily the mechanical side of the team, begin by sitting together as a group and throwing out ideas for the project. Team members strive to remain open to ideas and to not dismiss any in the beginning.

The brainstorming process may prove to be challenging because the team is assigned tasks that provide a narrow time frame and a scarce amount of leeway.

Sophomore Miles Olson, a programming lead of ART, explains, “We’re given the tasks so suddenly and then we have very little time to come up with a design and mechanism. So brainstorming can often get very hectic, and what we try and do during the brainstorming phase is to not say any ideas are good or bad. We just take anything and we’ll think about it later. That way, we can get a ton of ideas.”

Uri Geva, one of several parent mentors of ART, elaborates on how brainstorming necessitates team members to be receptive to a wide range of ideas. He says, “In brainstorming, when people come up with ideas, a stupid idea will sometimes cause another person to think about something that is very interesting. So there is no such thing in brainstorming that is stupid.”

A lack of experience among some team members may additionally prove to be an obstacle during brainstorming. Senior Candy Zhang, co-caption of ART, says, “If people don’t have that much experience, they might not think of an idea that is simpler because they don’t know that it exists.”

The team eventually begins to filter out ideas through a process of elimination. Sophomore Jason Yang, another ART member, says, “Basically, we go over pros and cons of each idea and see which ones are best in terms of buildability, efficiency, strengths and weaknesses strategy-wise, et cetera.”

Step 2: Prototyping

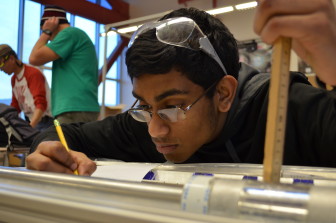

The team builds models of their ideas using relatively cheap materials and tests them during prototyping. Materials the team uses include wood, white PVC and black ABS pipes, and string. Later, the team uses aluminum to better model the real robot.

Prototyping can be a difficult process. Olson says, “When we get to the prototyping, things become significantly harder, because we have to sort out a lot of bad ideas and settle on one design. A lot of problems get solved by just making small models out of cheaper and easy to use materials, and testing to see if they will work in a full model.”

Prototyping occurs throughout the robot-building process as the prototypes become increasingly finer to better model the final robot.

Step 3: Machining, Assembling, and Programming

During the machining and assembling process, the mechanics, electronics, and programming work together to produce a functional and completed product. “The mechanical side is all about the brainstorming, prototyping, machining, and then assembling,” says Olson. “And then there’s the underside, which is everything that makes the robot do things, which is mostly the programming but also the electronics. I guess you can say the electronics are the intermediary between the physical design of the robot and all of the technical programming.”

The team produces and assembles individual parts manually and uses the tools in the engineering tech shop to do so. Some of the parts that the team buys are built beforehand, but most parts are custom-made to achieve precisely what the team desires.

The team hopes to improve from its mistakes last year. Olson says, “We always look at the mistakes we made last year and learn from it. What we plan to do this year is to make things easy to repair on the fly. In general, we need to be more organized by having more concrete design, so that we can see the problems when it’s in the building phase.”

The robot will eventually ally with those of other teams to compete in the Central Valley Regional and later the Silicon Valley Regional. Olson adds, “I look forward to showing off our robot in the competition and seeing how we do against some of the best teams.”