Because of Aragon’s problem with black mold in classrooms as a result of flooding, many teachers have been forced to adapt their classes. The Engineering and Tech classes’ new 3-D printer is one such adaptation.

Due to this problem, science teacher Arron Apperson’s Engineering and Technology class no longer has access to its metal-working machines. To compensate, the classes now use their new 3-D printer, stored in the Computer Lab in room 253.

The printer was paid for by the district. Apperson says, “They recognized that all of us teachers that were affected by the mold issue had parts of our class, parts of our curriculum [taken away], so this comes from insurance money.”

The first part of Apperson’s back up plan is to make the students create Legos that they’ve lost in the past using the machine. “Children lose Legos, even high school kids lose Legos, and their first task will be to draw the Lego pieces that they lost and then we’ll print them out here rather than me order from Legos.”

Even though the printer was bought because of the mold, it will stay at Aragon under Apperson’s control because he is the current Engineering and Technology teacher.

Because of this, robotics can use the 3-D printer to make soft and hard plastic parts for their robots. “When they think about robotics, putting in a flexible knee joint with two hard plastic pieces on either side actually works very well, because your leg is essentially nothing more than a spring, and putting a spring in the right places allows you for biomimicry.”

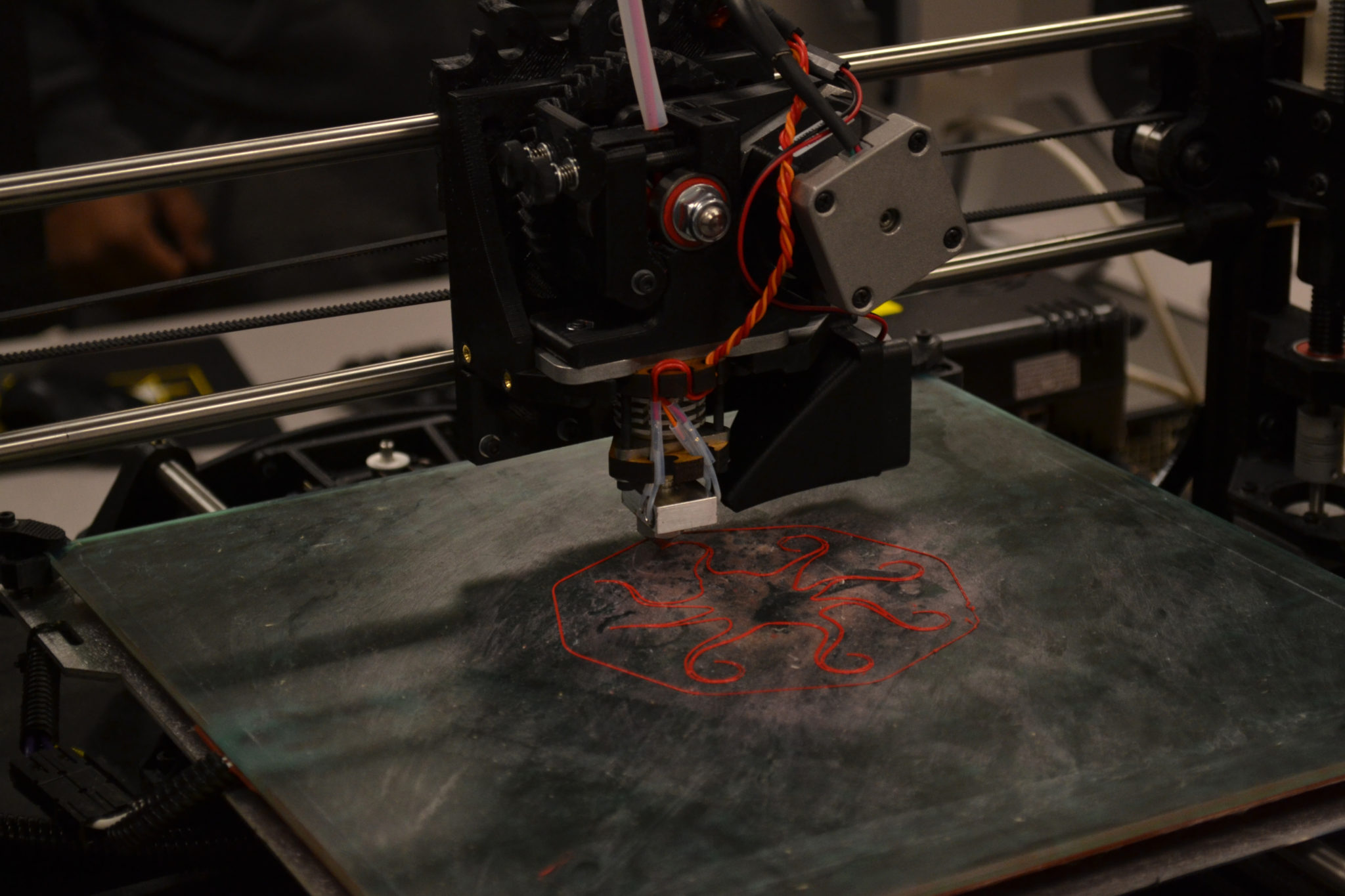

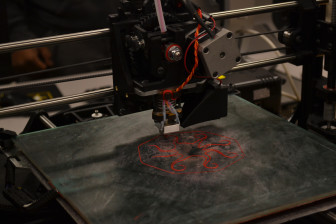

The 3-D printer has plastic wires wrapped to itself and melts them on a tray where it cools. The printer is controlled by computer programs that transform the 2-D sketches into the final 3-D. “It puts down the first layer first and then it goes up on these screws and then it lays down the next layer. It’s actually printing two-dimensionally but it stacks on top of itself.”

Because the printer is still new, Apperson is still trying to get new parts and see if Robotics can recreate the parts needed for a 3-D printer to make a second one. “I’m also interested in getting a second extruder that will do two colors, not just one color, and there’s another extruder that’ll do [hard] plastic and a flexible plastic at the same time,” adds Apperson.

Until the printer can be moved back into the Engineering and Tech classroom, it will stay in the computer lab where it will be constantly in use. “There will be days when this computer lab will be needed by other classes and this printer will be printing,” Apperson says. This is because the machine can take at least an hour to print out a small object. The colors and sizes also make the finish time vary.